Chemical zinc oxide manufacturing is rarely used due to its high operational costs. This technique involves reducing zinc oxide with hydrogen or carbon monoxide gas at extreme temperatures to form pure zinc, which is then cooled and converted into very fine particles.

Zinc Oxide Manufacturing Process

The initial stage in zinc oxide manufacturing begins with the preparation of the base material. The main component used is pure zinc metal (Zn) with a purity of at least 99.9%. This material is generally obtained from processing sphalerite ore (ZnS) through electrolysis or controlled combustion.

The purified zinc is then formed into ingots to facilitate handling and feeding into the melting furnace. Cleanliness of the base material is crucial because the presence of foreign substances such as iron, lead, or cadmium can degrade the quality of the final product. These contaminants have the potential to affect particle size distribution, reaction stability, and the consistency of the resulting zinc performance.

Smelting Process

This next stage in production involves melting the zinc metal, which is carried out using a special furnace with high heat resistance. The operating temperature range is generally between 900–1,000°C until the zinc material reaches the liquid phase. During heating, atmospheric control is essential to prevent excessive oxidation reactions.

The formation of zinc oxide (ZnO) can reduce the efficiency of zinc dust production, so stable process conditions are crucial. Furthermore, precise temperature control plays a role in maintaining consistent final product quality.

Evaporation

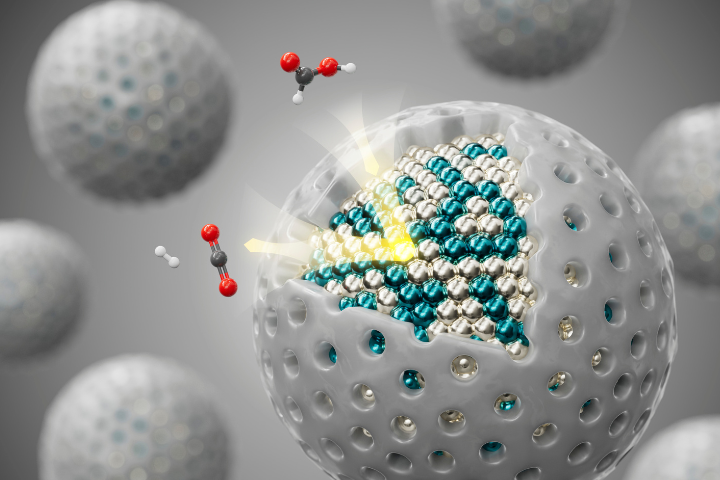

The next stage involves evaporation and condensation, which are key components of zinc production. The zinc metal vapor formed from the melting process is directed to a condensation chamber at low pressure.

Purification

At this stage, the resulting powder still has varying grain sizes and residual oxide compounds. Because of these conditions, purification and precipitation processes are necessary to separate large particles, zinc oxide, and other impurities.

This stage can be achieved through mechanical separation using air filtration or centrifugation techniques. In addition to increasing purity, this process also plays a role in stabilizing the quality of the final product to meet industry standards.

Sieving and Classification

The next stage involves sieving and particle size classification. Zinc powder needs to be tailored to specific specifications to meet the demands of various industrial sectors. In the production of anti-rust coatings, very fine grains are required to easily combine with the binder.

The zinc oxide manufacturing process is a series of controlled steps designed to produce zinc powder with a level of purity, particle size, and consistency that meets industry standards. From raw material selection, melting, evaporation, to cooling and sieving, each phase plays a critical role in maintaining the quality of the final product.